Organic light-emitting diode, or OLED, displays are not uncommon in our current day and age ”” many of us have them right in our phone screens.

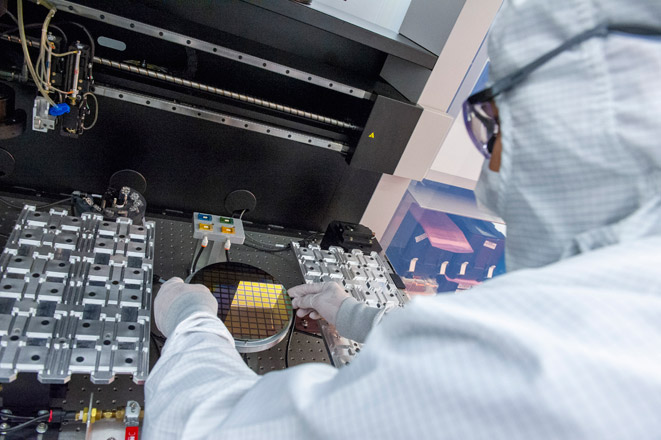

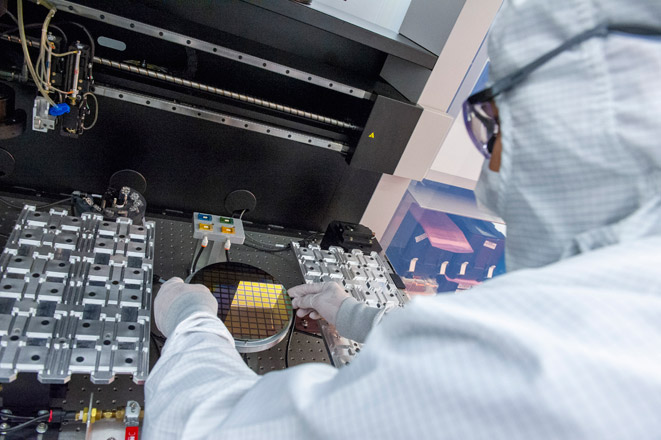

eMagin is the only manufacturer of OLED microdisplays in the United States, which are smaller and of a higher resolution than normal OLED displays. An OLED TV, for example, might have 1,920 by 1,080 lines of resolution. eMagin”™s microdisplays can pack a higher resolution into a chip that is an inch or half-inch wide.

The result is a product that is more powerful, efficient and compact than other microdisplay industry alternatives, which are valuable in several areas.

“We sell a lot to the military in the form of aviation helmets, weapons sights, night vision, thermal imaging training, and the like, for the military side,” said Mark Koch, acting CFO at eMagin Corp. in Dutchess County. “We also sell to some medical customers in the eyecare market (for ocular surgery) and also in the veterinary market, for the use of viewers for ultrasounds.”

Along with those streams, virtual and augmented reality devices are becoming more popular and many high-profile companies are looking toward OLED microdisplays to fulfill their visual needs for those devices.

Military purchases, both U.S. and foreign, make up roughly 60% of eMagin”™s sales, with industrial, medical and commercial/augmented and virtual reality all making up significant portions from 10% to 20% as well.

The company was founded in 2000, and is located now, as it has been for years, at the former IBM facility known as iPark in East Fishkill.

When eMagin came to East Fishkill, it had not only a highly technologically capable campus waiting, but also a large talent pool of former IBM employees. Since then, the company has developed considerably.

“We invented the first commercial OLED in 2000 and then we”™ve been successively ”” through our R&D efforts and some in partnership with the government and commercial companies ”” making them sharper, brighter, some of them a little larger,” Koch said. “We”™ve increased our resolution over the years.”

Now, it”™s over 100 employees strong and making revenue in the range of $25 million to $30 million annually, and is set for a new expansion from federal grants of roughly $39 million, to support its manufacturing abilities at iPark.

The grants are from the Department of Defense; as eMagin is the only domestic OLED microdisplay manufacturer, the military has a stake in expanding and strengthening its production. With the funding, awarded in the summer of 2020, eMagin will be able to upgrade equipment.

“We”™re putting our display into a helmet for the F35 fighter jet, we”™re putting it into night-vision goggles, which are used by U.S. military special forces,” Koch said.

“The military really likes these OLED displays because they”™re high resolution, they use very little power, they”™re very bright and they”™re very rugged. So part of the reason was to support us as a company, as the only company in the U.S. manufacturing these, and the military has a strong buy-American component … so it”™s just part of the military wanting to protect their supply chain and keep up as much domestic manufacturing for military products as possible.”

The $33.6 million comes from a Defense Production Act Title III program grant, with funds authorized and appropriated from the CARES Act, intended to help replace and update aging equipment to increase output and allow the company to retain and expand its staff.

The other $5.5 million are marked under the Industrial Base Analysis and Sustainment (IBAS) Program, for supply chain assurance for eMagin”™s OLED manufacturing. Installation of capital equipment is the main purpose for it.

“This is a significant grant in terms of our equipment,” Koch said. “When you look at the book”™s value of our equipment, it”™s around $9 million. So we”™re receiving a $39 million grant to upgrade and expand our factory equipment. So this is a huge grant for us where, you know, we”™re very excited about it. It”™s going to improve our efficiency and our capacity and our output and a large part of it is for a new tool to really advance our direct patterning technology.”

The first of that $39 million has been spent on an advanced wafer inspection tool valued at $1.1 million, delivered in January.

Along with that grant comes one from Central Hudson Gas & Electric Corp., through a Wireless Innovations and Job Creation-Attraction economic development program. It goes hand-in-hand with the federal funding. It will contribute $100,000 more toward the expansion, and support job creation with a grant equal to $1,000 per job for positions in manufacturing paying more than $40,000 annually, up to $100,000.

“Central Hudson has a tradition of supporting companies that are looking to invest and bring well-paying jobs to the Mid-Hudson Valley through our economic development programs,” said Anthony Campagiorni, vice president of customer services and gas operations at Central Hudson. “The Covid-19 pandemic made it clear that a renewed focus on domestic manufacturing is critical and so we wish eMagin great success as they continue to expand their operations in East Fishkill.”

eMagin plans to create at least 18 jobs in its facility, 13 of which will be manufacturing, three of which will be in research and development and two of which will not be related to manufacturing.