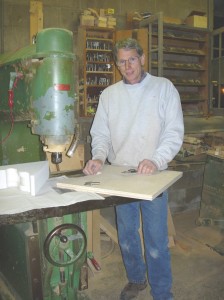

“Working with wood, you get to know the personalities of the different species,” said Edward S. Pryor, owner of Federal Cabinet Co. Inc. of Middletown.

“Tooling needs to be sharpened and machinery properly set for harder and softer woods,” he said.

Maple and oak qualify as harder woods; poplar, medium, and cedar and pine, soft.  He is sad at the demise of the chestnut trees, once popular for trim work in older houses. Ash, a hardwood, is probably destined to go the way of the chestnut, Pryor believes, following the invasion of the emerald ash borer for which there is no known antidote.

“Ash is specified by some of my customers. I personally like it because it machines well and has a nice sunny look. In the short term the emerald ash borer is not affecting the supply of ash lumber, but I fear that in the future it will become non-available.”

Raised in Central Valley, Pryor was the younger of two sons of parents who owned a small shop in Harriman that made lamps and lampshades. He recalls that in the early l970s wooden lamps became fashionable. “Dad could not manufacture enough wooden parts in Harriman. I was working in construction, and there was a shop for sale in Middletown that did woodworking. ”˜You can make the parts for me and anything else you want to do,”™ my father told me, offering financial incentive. I was age 23 at the time.”

The shop was owned by a woodworker of Belgian background. “He stayed on and mentored me for a number of years,” Pryor said. “We used to do the guitar and banjo necks. And we started making small furniture pieces that would go well with dad”™s lamps.

“After a decade or so the lamp industry began to die off because of imports. I found I had the ability to make parts very well. Driving around, I noted the homes built in the early l900s were becoming in need of repair and was able to reproduce required parts with the type of machinery that was originally used. My mentor was good at fixing machines, as we had to keep the older machines running well.

“I feel particularly good about doing architectural restoration work. A lot of the old designs and craftsmanship you see are really clever. It is very satisfying to help retain the beauty of older homes.

“We also make wood parts for other manufacturers: jewelry, bracelets, rollers for a carpet mill, furniture parts ”“ high production like 1,000 identical legs. I love figuring out the best way to make a part efficiently.”

Pryor generally works with wood from the Northeast. “Oak, cherry and maple are popular,” he said. The Federal Cabinet Co., when possible, uses wood certified by the Forest Stewardship Council, which verifies that the lumber is obtained from renewable sources and managed forests. “More and more customers are interested in obtaining FSC products,” he said.

Pryor has a dedicated partner in his wife, Patricia, who was working in a newspaper art department when he met her and who now manages the business end of their enterprise. “She keeps me from spending too much money.”

They are the parents of two college students. Son Edward is a junior at Rensselaer Polytechnic Institute in Troy studying electrical engineering, and daughter Paula is a freshman at Juniata College in Huntingdon, Pa., planning to specialize in geology and environmental science. The family enjoys sailing and owns a sailboat at Lake Wallenpaupack, west of Milford, Pa.

Challenging Careers focuses on the exciting and unusual business lives of Hudson Valley residents. Comments or suggestions may be e-mailed to Catherine Portman-Laux at cplaux@optonline.net.