Yonkers Contracting Company Inc., which is known far beyond the city limits of Yonkers by virtue of the more than 1,350 projects it has completed valued at approximately $13 billion throughout Westchester and the New York Metro region, is celebrating its 80th anniversary.

The company was founded in 1945 by Edward Petrillo and now is led by his son Carl. The company, originally known as Petrillo Contractors, has called Yonkers its home since its founding. It recently upgraded its equipment facility and storage yard on Midland Avenue in the city, where the company maintains a fleet of some 350 pieces of heavy-duty equipment used in its construction projects. The number of employees at any given time depends on the number and scope of projects that are underway.

The company recently held an anniversary celebration at its Midland Avenue facility. Among those attending to congratulate Yonkers Contracting on its achievements and longevity were Westchester County Executive Ken Jenkins, Yonkers Mayor Mike Spano and Westchester County District Attorney Susan Cacace.

Literally millions of motorists are familiar with the name Yonkers Contracting by virtue of having seen it on equipment at paving and other road projects. However, many may not realize that the company has been responsible for major, complex construction projects such as the World Trade Center PATH Restoration Program following the 9/11 attack, which involved restoring critical transit links for the Port Authority.

The company’s single largest project has been the Design/Build Contract for the New York State Department of Transportation on the Bronx River Parkway to replace a multi-span bridge over an MTA train yard with a new 1,500-linear-feet viaduct. Other landmark projects include the Brooklyn Bridge Emergency Deck Replacement, building the LaGuardia Airport East Parking Garage, and a Design-Build Project to reconstruct the highway interchange of Route 17 and Route 32 in Orange County.

The company also was responsible for reconstructing I-684 from the Saw Mill River Parkway to Brewster. The company replaced a bridge on I-95 over the Saugatuck River in Westport, Connecticut, using a revolutionary technique in which the new bridge is constructed in parallel with the existing bridge and then slid into place.

Last year, Yonkers Contracting managed the emergency replacement of the Fairfield Avenue Bridge on I-95 in Norwalk, which had been severely damaged by a tanker truck fire. The damaged bridge was quickly demolished and I-95 reopened for the Monday morning rush hour after the accident. Yonkers Contracting and its subcontractors had the new bridge constructed a couple of months ahead of schedule and about $3.5 million under budget.

The company has handled projects at Penn Station and Grand Central Terminal as well as work at water and wastewater treatment facilities and commercial buildings and sites.

“It starts with and ends with our most important resource and that’s our people,” Petrillo told Westfair’s Westchester County Business Journal. “When you’re determining what you’re going to build those are mostly scientific decisions. When you come to the actual execution of the work and how to build there still is some science and the sophisticated techniques we use but what comes into play is common sense that comes from very experienced hands. They started in the trades and could have been carpenters, laborers, operating engineers, ironworkers. The guys that did it every day are the guys that know what is the most efficient approach to the challenge of construction.”

Petrillo said that when he first started in the business he was told that if he wanted to get something done he needed to talk to his crew and not down to them.

“Even with all of the sophistication and advancement in technology this is very much still a people business,” Petrillo said. “This is a relationship business, relationship between upper management and the people who work for them; the relationship between upper management and the people who inspect the work; and the owners representatives.”

The importance of people was echoed by Jack Donnelly, vice president and project manager for Yonkers Contracting who has been with the company for 28 years.

“The secret of our success is that we have people here who want to be here and stay here for a long period of time. You have this incredible expertise,” Donnelly said. “I really credit that to Carl Petrillo. He’s very involved in every bid. He sets where we’re going. He’s steering the ship. He has the vision and the leadership. That’s why I came here.”

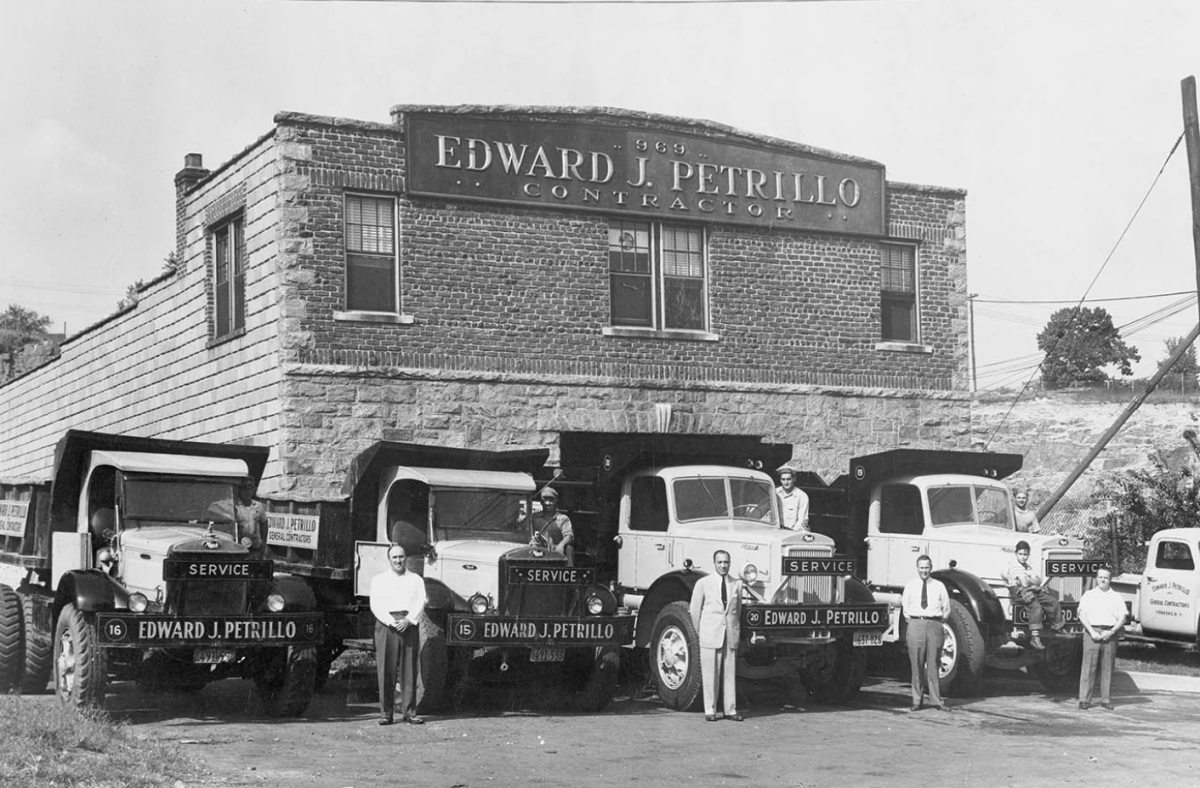

Petrillo Contractors in the early 1950s – Edward Petrillo standing in front of the third truck from the left, young Carl sitting on the bumper of the truck on the right.

Bill Jordan, formerly senior vice president of construction who retired in 2022 after 39 years with the company said, “Carl wants you to think out of the box. He promotes that and rewards that.”

Paul Hubert, who started out as project engineer and retired in 2022 after 48 years with the company, recalled, “It’s pretty remarkable what we’ve done over the years. Such massive projects. I can’t go anywhere in the metropolitan area without driving by three or four things that I helped change the landscape. It’s pretty incredible.”

Petrillo said that the majority of the work Yonkers Contracting undertakes is for government entities and because of complex bidding and contracting processes a construction company may only have eight or 12 weeks to study plans, estimate costs and complete bidding paperwork for a project that may have been in the design stages for one or two years.

“We’re exposed to the elements,” Petrillo explained. “Most of what we do depends on the weather that’s outside. You try to figure out average rain days, average snow, cold, hot.”

Petrillo said that the rebuilding of the PATH System at the World Trade Center is one of the projects of which he’s most proud.

“We finished the job early and employed thousands of people while we were rebuilding it,” Petrillo said. “The Williamsburg Bridge was a very big job for us 30 years ago where we replaced the north side access and built a big box structure for bicycles and pedestrians to cross. It was a very challenging project because of the amount of steelwork.”

Petrillo said that the company has benefitted from incorporating new technologies such as computer-aided design, lasers and GPS, not only because they can save time and money but because they can result in construction done with a level of accuracy that far surpasses what was previously possible.

“It is insanely accurate and basically easy to operate,” Petrillo said in describing how measuring with lasers was a major step forward in terms of measuring grade and establishing layout dimensions. “Then came the satellites (GPS) connected to a lot of construction equipment today. The machine is told how to grade a particular area. It’s remarkable how clean the digging and grading functions now are. Here in our office we have apps we have developed to replace paper trails.”

Petrillo said that information technology has reduced the time is takes for people to collaborate and has increased efficiency.

Petrillo said that the attention paid by the company to environmental needs is reflected in some of the types of jobs it undertakes such as for a new water filtration plant on property at the Westchester County Airport but also in its modernized maintenance facility on Midland Avenue as well.

“When we clean the equipment the water goes into a drain tank and it goes through a filtering system,” Petrillo said. “The water we discharge is clean and we take the debris that is removed to a licensed dumping place. On the jobs, we pay a great deal of attention to erosion.”

Petrillo said that safety is an extremely important part of the business both in terms of protecting employees on the job and ensuring safety of the public in proximity to construction sites.

“We have a very complex program of safety awareness that includes meetings every morning with the foremen, superintendents of the projects, to go through the work for the day and how we’ll approach it safely,” Petrillo said. “We’ve gotten dozens of awards for our safety record without any lost man hours.”

Petrillo said that not only does the company have an obligation to keep its workers safe, but doing that can result in lower insurance premiums that can reduce the cost of a job and help the company meet safety requirements that may be included in bid specifications.

Petrillo said that he’d like Yonkers Contracting to be thought of as a company that “provides gainful employment, has a social conscience and renders a distinctive service to its clients. The reputation of the company builds confidence in the company’s ability to do the work. How you start the job, how well it goes, determines the success.”