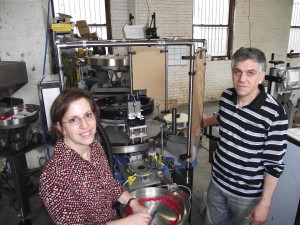

At her mom-and-pop manufacturing business in Mount Vernon, Deborah C. Smook hung a new black-plated plaque on her office wall. She and her husband, Eli Uriel, paused to admire it, if only briefly. With a large export order to fill for a foreign client that could open more corporate doors to their small company, there was little time to savor their recent distinction.

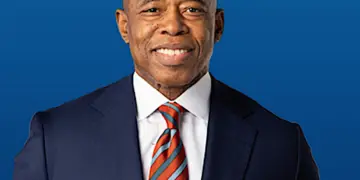

The U.S. Small Business Administration”™s New York district office in April honored the couple”™s 12-year-old company, TurboFil Packaging Machines L.L.C, with its Exporter of the Year Award. The SBA recognized TurboFil”™s growing export business and particularly the sale of a custom-built, highly specialized parts assembly system for an Israeli defense contractor. TurboFil closed the deal, which Smook said amounts to more than $1 million, after her nine-month effort to get a bank”™s credit backing for the foreign sale and shipment.

The couple employs 10 workers at TurboFil, which designs and builds liquid filling and assembly machines and systems chiefly for the cosmetics, pharmaceutical, diagnostic and chemical industries. Prices for the company”™s benchtop machines range from $1,500 to $15,000, Smook said, while larger floor machines, used by packagers to fill and assemble products that include nail polish and perfumes, nasal sprays, liquid pharmaceuticals, syringe injectables and dental and veterinary products, sell for $20,000 to $50,000. Full mechanical systems can range in price from $250,000 to $500,000, she said.

In her acceptance speech at an SBA ceremony in Manhattan, Smook called TurboFil “an example of the new American manufacturer. We are a small company competing with giants from all over the world and winning sales based on customization and personalized service. We can be competitive internationally because our products demand a high level of technology, engineering and capital to produce.”

“We don”™t get the easy stuff,” she said in the Mount Vernon office, where visitors are warmly greeted by Pepper, the family”™s Chatham Hill retriever. “We do very custom and customized machines. Every product we get has something unique about it, so we never build the same machine twice.”

Brainstorming a business plan

Smook, TurboFil”™s vice president of marketing and business development, holds a degree in electrical engineering. She worked in marketing and business development for a consulting firm in medical and pharmaceutical devices until about six years ago, when the couple decided that “with the two of us pushing it, we could make it just on the business,” she said.

Her Israeli-born husband, a dual citizen of the U.S. and Israel, is a mechanical engineer. Uriel previously worked for a contract packager in the U.S and more recently for a New Jersey company that made filling machines.

“The company wasn”™t doing very well,” said Smook. “He thought he could do it better. He found himself a customer and started.”

That was in 1999. In a brainstorming session at their dining room table, Smook and Uriel came up with a company name that would be recognized in other countries and languages.

Uriel initially leased 1,300 square feet of space in a Bronx machine shop, while Smook, raising their two small children, did the company”™s office work from their Riverdale home. Five years ago, they moved the growing business to a 7,000-square-foot space in a former furniture warehouse on the Bronx border at 30 Beach St. in Mount Vernon.

Smook unsuccessfully sought to transfer TurboFil”™s tax credits in New York”™s now-expiring Empire Zone program to the company”™s location in a Mount Vernon Empire Zone. The shift required a resolution of the New York City Council. “We did everything but hire a lobbyist,” she said. “I wasn”™t willing to go that far.

“I don”™t think in the first year we sold more than one machine. Then slowly, slowly things started to build.

“We weren”™t really looking for exports in the beginning because the U.S. market is big enough,” said Smook. The recession, though, “affected our domestic business quite a lot, so we focused more on the export market,” where the weakened dollar made American products more attractive to foreign buyers.

”˜An award for patience”™

Smook began advertising more heavily on the Internet, using Google AdWords to draw international viewers to TurboFil”™s website. “We started getting leads,” she said.

Four years ago, the company made its first export sale when a cosmetics company in the Philippines placed an order for two nail polish fillers. “They found us on the Internet,” Smook said. “Most of our business comes from leads that come through the Internet.”

About two years ago, the couple heard of the parts assembly project by an Israeli defense contractor. Part of the federal Foreign Military Financing program managed by the U.S. Defense Department, the project required the foreign contractor to purchase American-made equipment to qualify for U.S. government funding.

TurboFil competed with four other companies for the project, details of which are confidential. “We spent a lot of time doing a custom design for them,” said Smook. “Eli is a brilliant designer. That”™s really allowed us to do what we”™ve done. He”™s creative and he”™s been able to come up with a better way that also costs less. He comes up with a simple and elegant design.” It won over the Israeli company.

Smook, though, met with repeated rejection by banks when trying to obtain credit approval and the bank”™s letter of credit to guarantee the buyer”™s deposit will be repaid if TurboFil defaults on the deal.

“Our bank, Chase, told us no,” although TurboFil already had the backing of the SBA”™s Export Working Capital program. The program guarantees payment to commercial lenders for 90 percent of the loan amount, up to $4.5 million, if a business borrower defaults. Chase said the company lacked an adequate cash reserve.

Smook made the rounds of banks. “Big banks mostly weren”™t interested because we”™re small,” she said. “And in 2009, the banks weren”™t interested in anybody” applying for credit.

“TD Bank came through for us” with the credit authorization, she said. “They were right with us from the beginning. It took a long time but ultimately they approved it.”

Though no federal or private money was loaned to TurboFil”™s owners to manufacture the system, obtaining the letter of credit took nine months. “I say this is an award for patience,” said Smook, nodding at the newly hung plaque.

Growth in exports

TurboFil has added one employee to complete the Israeli project by the fourth quarter this year. “Before the contract, everybody was working reduced hours because 2009 was so bad,” said Smook.

For TurboFil, “There”™s obvious potential with this customer, assuming they”™re happy” with the delivered system. “This product can also be sold to other projects. And it showcases our capabilities,” she said. “With a small company, you”™re always trying to demonstrate your capability.

“Our competitors are usually much bigger than us. That”™s a challenge for us, because sometimes corporations are wary of dealing with a small manufacturer. And we”™ve lost sales because of that.”

Their competition is international and especially strong in Canada, Italy, Germany and Spain, said Smook. “We would love to break into Europe,” she said. TurboFil now has a representative in the United Kingdom bidding on a project there.

Though the company has sold to a Romanian client, western European countries “are very hard to break into,” she said. “The European Union is very strong. Their companies get a lot more assistance than we do” from government, she said.

Excluding the large Israeli contract, exports now account for about 20 percent of TurboFil”™s business, said Smook.