The mood in late June was one of celebration, mutual congratulation and anticipation at a gathering at the manufacturing facility of Protein Sciences Corp. on the quiet Pearl River campus of Pfizer Inc.

Employees of Protein Sciences, many of whom had been laid off by Pfizer as the biopharmaceutical giant in recent years phased out operations on its 500-acre Middletown Road site, mingled in an office atrium with public officials and other guests, who donned protective garb to tour Protein Sciences”™ 83,000-square-foot plant.

This year has been a good one for Pfizer”™s tenant of about 2½ years in Rockland County. A 32-year-old, privately owned Connecticut company with headquarters in Meriden, Protein Sciences survived bankruptcy in the 1990s and more than a decade of costly clinical trials for Flublok, its technologically innovative influenza vaccine brand, to emerge as a favored company of federal agencies in the government”™s effort to improve the nation”™s readiness and production capacity in the event of a flu pandemic.

That favored status was highlighted this spring, when the U.S. Food and Drug Administration licensed the biotech company”™s Pearl River facility for the commercial manufacturing of Flublok and also moved to protect the novel vaccine”™s maker from new competitors while it develops its manufacturing operation.

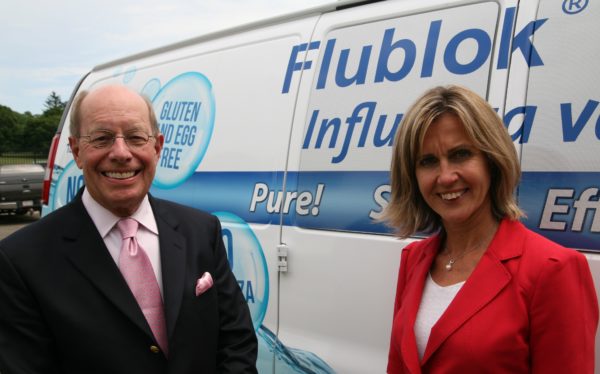

- Daniel D. Adams, Protein Sciences Corp. executive chairman, and Dr. Manon M. J. Cox, president and CEO, outside the company”™s flu vaccine manufacturing plant in Pearl River. Photo by John Golden

Flublok”™s development and commercialization have been supported since 2009 by $149 million in grants to Protein Sciences from the federal Biomedical Advanced Research and Development Authority. BARDA was created in 2006 to work with private industry to develop flu vaccines using advanced technologies to build up the nation”™s vaccine inventory in the event of a flu pandemic. BARDA has set for Protein Science a production capacity goal of 50 million doses in a six-month period.

Unlike traditional flu vaccines, Flublok is not made using chicken eggs or infectious influenza viruses. Instead, Protein Sciences, applying a technology that company executives said is about 35 years old, uses recombinant DNA and a modified virus that infects insects to produce large quantities of hemagglutinin protein, the active ingredient in flu vaccines. Protein Sciences officials say Flublok is the world”™s first licensed influenza vaccine made using modern recombinant technology.

A top official at the U.S Department of Health and Human Services called the FDA”™s approval of Flublok, which has been produced at the company”™s manufacturing facility in Meriden since 2013, “one of the most significant improvements in flu vaccine technology in the past 50 years.”

The FDA”™s manufacturing approval was “a critical milestone” in the company”™s development, Manon Cox, president and CEO of Protein Sciences, told the crowd of well-wishers in Pearl River last month. She said the former Pfizer plant has a production capacity four to five times greater than the Connecticut facility, which can produce 500,000 to 1 million vaccine doses. The company will make 1.2 million doses this year, she said, adapting much of the equipment left by Pfizer when it stopped manufacturing a children”™s vaccine.

Cox said it was “a pleasant surprise” to company officials when in late spring the FDA in a rare move granted regulatory exclusivity to Flublok for a period of 12 years. With the agency”™s action, no product similar to Flublok can be approved by the FDA before January 2025, 12 years after Flublok”™s initial approval for use by adults from the ages of 18 through 49.

Cox said the FDA designation “prevents a generic product maker from capitalizing on the hard work of our team” and will give Protein Sciences “an important competitive advantage to help with the commercialization and development of this vaccine.”

Attorney Tom Kowalski, who represents Protein Sciences, said it was only the third such exclusivity granted by the FDA under the Affordable Care Act and the first for an influenza vaccine.

At the June celebration, Protein Sciences executives also announced the results of a clinical trial that compared Flublok”™s quadrivalent vaccine ”” which protects against four different influenza viruses ”” with a traditional egg-based quadrivalent vaccine. The study included about 9,000 people aged 50 and older.

The results showed that 31 percent more people were protected against influenza by Flublok than by the traditional vaccine. Cox said 3.2 percent of subjects given the licensed egg-based vaccine caught the flu, while 2.2 percent of those who used Flublok were flu-bitten.

Federal officials have said the Flublok manufacturing process can be used to more quickly meet increased demand for vaccine in seasons when the flu is widespread and potentially for a pandemic vaccine because the technology does not depend on an egg supply or the availability of influenza virus to start production. And Protein Sciences officials noted that the company”™s protein vaccine is not susceptible to the mutations that flu viruses can undergo in eggs, making them less effective against the season”™s flu strains.

In flu vaccine manufacturing, “What you do today in six months, you could reduce by one, two, three months” using Protein Sciences”™ technology, said Albertus Osterhaus, a virologist and veterinarian who serves on the company”™s board of directors. “I think it”™s very promising news for the future.”

Cox said she thinks the novel flu vaccine technology developed in Meriden will eventually replace traditional egg-based production, but “not immediately. I think it”™s a process that takes approximately 10 years.”

With the FDA”™s green light to manufacture in New York, Protein Sciences expects to hire an additional 70 employees at the Pearl River facility, which has 32 workers, according to a company spokesperson. Cox said the company produced its first Flublok batch within 100 days of taking over the plant, getting a jump-start from former Pfizer employees with working knowledge of the facility.

Protein Sciences took over a facility “that was basically plug in and play,” said Michael DiTullo, president and CEO of the Rockland Economic Development Corp. Cox said that ready setup limited the company”™s investment in opening its New York facility to $20 million.

“The poster child for the biopharma company that we want in our region is Protein Sciences,” said Al Samuels, president and CEO of the Rockland Business Association and a director on the state”™s Mid-Hudson Regional Economic Development Council. “You are making an impact on the entire region” and will attract other biopharma companies to the Hudson Valley, he said at the June celebration. “It is a vital addition to our landscape.”

How long Protein Sciences will remain on that landscape is uncertain. “It all depends on how successful we are” in sales of the novel vaccine, Cox said.

The company”™s five-year lease in Pearl River expires in 2018 and comes with a five-year extension option. Protein Sciences is also looking at other manufacturing options, including sourcing products from Japan and a licensing partnership in Mexico that could be completed later this year, Cox said.

“We really want to expand here,” Daniel D. Adams, executive chairman and global head of business development at Protein Sciences, told the audience on the Pfizer campus. Adams, a successful biotech entrepreneur who rescued the mismanaged company from bankruptcy in the mid-”™90s, said he “would encourage other biotech companies to take a look” at the Pearl River site for their operations.

“We really see New York as the future of the country,” Adams said. But expansion depends on sales, he added.

“Our competitors are very big, very strong” and often misrepresent Flublok, Adams said.