Cementing concrete’s future in the HV

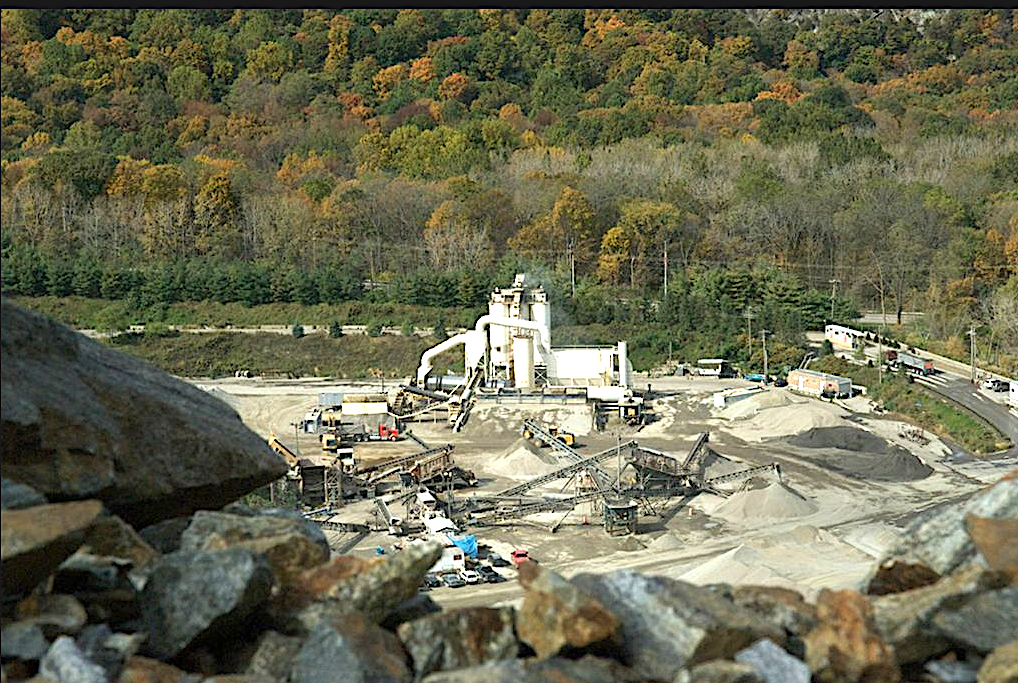

Thalle Industries believes in the future of the concrete business in the Hudson Valley along with the importance of recycling construction materials rather than dumping them into landfills. Thalle Industries’ CEO Glenn Pacchiana told the Business Journals that, keeping those things in mind, Thalle recently purchased the concrete manufacturing facility of Dakota Supply Corp. in Montrose. Thalle is launching Dakota Concrete and also is opening a Virtual Quarry recycling center at the 2099 Albany Post Road location.

While Thalle has launched its Dakota Concrete operation, Dakota Supply Corp. remains in business at the Montrose site providing other products and services as it has been doing for decades.

Thalle actually had been supplying raw materials to Dakota for it to use in its concrete manufacturing, which took place along with Dakota offering construction and landscape materials as well as hardscape and masonry supplies such as flagstones and pavers.

“Thalle Industries is an environmentally responsible producer of aggregates, asphalt and recycled products,” Pacchiana said. “We’ve got facilities in Fishkill and Elmsford. It seemed like a natural fit for us for a few reasons. We have a lot of the same customer base. We have been focusing at Thalle Industries on taking employees and promoting from within so we have a number of employees that have been maturing and growing and this seemed like a natural fit.”

Pacchiana expressed confidence that his existing employees are ready to move up to the concrete manufacturing business and that the workers already at the Dakota Supply Corp. concrete facility and his existing employees will fit together nicely. Thalle currently has about 65 employees.

“It’s a really good win-win opportunity for everybody,” Pacchiana said. “Concrete is the most-demanded construction material around the world. Asphalt is sand, stone, liquid asphalt. Concrete is sand, stone, cement and water. It fits in very well for what we do. We see a lot of demand on the infrastructure side. Concrete is a natural fit for us in our portfolio. We think that we’re going to be very busy with concrete in the coming years. There’s a lot of pent-up demand for infrastructure. There’s money for infrastructure spending that is out there.”

Pacchiana said that getting into concrete manufacturing and delivery to construction and infrastructure sites is going to bring new responsibilities to the company.

“My background is construction as are a number of employees of Thalle Industries,” Pacchiana said. “The whole key is to coordinate with the contractor. You want to understand what they’re doing. You want to make sure that you can make their life as easy as possible because they’re out there with crews that are waiting on us. In the concrete business, we’re a delivery company. It’s different than asphalt. In asphalt, we load the material into the contractors’ trucks. In concrete, it’s our responsibility to get the material to the job. We’ve got very good relationships with our contractors and really try to put ourselves in their shoes. They have a crew out there; they may have a $15,000-a-day crew and you don’t want them waiting for your trucks. We have to understand what they need.”

Pacchiana explained that just as technology has brought improvements to so many things in life it also has brought improvements to the concrete business, allowing construction using concrete pours to continue into the winter months.

“The bottom line is you have to find a way to allow the chemical reaction to occur,” Pacchiana said. “You can heat the concrete, you can put warm water in it. It gets more expensive but the bottom line is we’ll work with contractors all the time. There are ways to solve problems. We’re very adaptable to work with any contractor in any situation. We can sit down with a contractor, find out what the problems are, find a solution and work with them.”

Pacchiana said that Thalle has made recycling a strong focus of its activities and by emulating its Elmsford recycling center at the Montrose site it will make recycling readily available for a larger swath of the Hudson Valley. As an example of the scope of what they’ve been doing in the way of recycling, he recalled that when the White Plains Mall was recently torn down the concrete from that site was brought to Thalle in Elmsford for processing so it didn’t have to go to a landfill. Steel embedded in the concrete was removed and various components separated and made ready for reuse.

“It’s our duty and our duty to our kids and generations to come to really be leaders in recycling so that as we are taking down old buildings and reclaiming old sites we’re cleaning the products as we go and trying to reuse and reincorporate everything without sending it to landfills,” Pacchiana said. “We are a privately held company that values its employees and we really are proud to be leaders.”