Westchester County and Wheelabrator extend contract for Peekskill plant

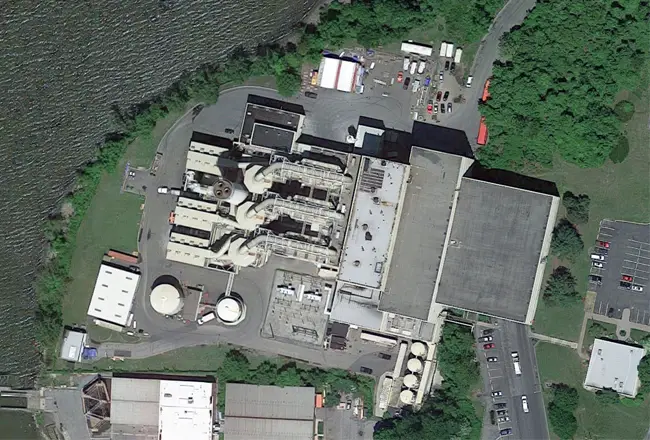

Westchester County”™s Department of Environmental Facilities has extended the contract for operation of the Charles Point waste-to-energy facility in Peekskill for another 10 years. The plant is operated by Wheelabrator Westchester LP.

It began operating in 1984 and processes up to 2,250 tons of waste each day while creating approximately 60 megawatts of electricity, enough to power 63,600 homes, according to Wheelabrator.

The company said that during 2018 the plant saved burning 729,515 barrels of oil that otherwise would have had to be used to generate electricity. It said 12,958 tons of metals were recovered from garbage hauled to the site.

The company said that during 2018 the plant saved burning 729,515 barrels of oil that otherwise would have had to be used to generate electricity. It said 12,958 tons of metals were recovered from garbage hauled to the site.

Waste is trucked to the plant by members of the county”™s Refuse Disposal District, composed of 36 of the county”™s 43 municipalities. The county said that the district includes 90% of the county”™s population.

The waste from households and commercial enterprises is burned in boilers that convert water into steam. The high-pressure steam is used to turn turbines which, in turn, make electric generators rotate. Excess steam is sold to a nearby commercial customer, White Plains Linen.

Vincent Kopicki, the commissioner of the Environmental Facilities Department, said the county looks forward to continuing the relationship with Wheelabrator. “They have proven to be excellent stewards of the waste-to-energy facility and our partnership ensures that the county”™s residential waste is not landfilled but used to create clean energy,” he said.

County Executive George Latimer said that an outgrowth of the contract extension will be an effort by the county to create a residential food scrap recycling program. He said that such a program would not only reduce the amount of waste going into the plant for burning but also could create cost savings.

“Since 2003, Westchester County has been able to reduce the amount of waste it delivers to the Wheelabrator facility by over 25 percent, which translates to millions of dollars in savings each year to Westchester County residents,” Latimer said.

The Peekskill plant was the subject of a case study released by the American Chemistry Council in 2011. It was prepared by Eileen Berenyi of Governmental Advisory Associates Inc., a solid waste and environmental consulting firm in Westport, Connecticut. The report noted that the metals recovered at the plant had been generating approximately $3.4 million in revenues, half of which went to the county. The study noted that in 1996, the plant underwent a $75 million replacement of its air pollution control system.

The study traced the history of the plant, noting that in 1972 the county first considered a waste-to-energy option after the federal government took it to court because the Croton Point dump was leaking toxic liquid and garbage into the Hudson River. The court found that the county had been violating various laws and ordered it to stop dumping at Croton Point as soon as possible and find a more environmentally acceptable alternative.

The county and federal government didn”™t reach a final settlement until 1975 and the county was required to come up with long-range plans for solid waste disposal, which would have to include resource recovery if economically feasible.

In 1978, then County Executive Alfred DelBello recommended to the county”™s board of legislators that a waste-to-energy facility would be the best solution. In July 1981, the county signed an agreement with Wheelabrator-Frye to build the plant.

The study said that in its first 25 years, the plant had resulted in keeping approximately 15 million tons of waste out of landfills.