Bridgeport takes green energy lead with thermal loop

Bridgeport”™s plan to become the first U.S. city to establish a municipal low-temperature thermal heating district has taken a giant leap forward, following the long-awaited passage of Connecticut”™s $41.3 billion state budget.

The city”™s thermal loop will use a network of underground pipes to distribute energy produced by a fuel cell or a combined heat and power facility to supply space heating and domestic hot water to Bridgeport”™s downtown buildings. In essence, waste heat from industries and from electrical generation is converted into heating and hot water for end users. The result will be what supporters consider a more reliable, environmentally friendly and cost-effective energy source than coal or natural gas.

“The city prides itself on being a leader in sustainable efforts,” said Bridgeport Mayor Joseph Ganim. “The beauty of it is the simplicity. It makes good environmental sense while saving money.”

Ganim, who has proposed various green, sustainable initiatives throughout his mayoral term, noted that the thermal loop project last year won Bridgeport the Climate Protection Award of the U.S. Conference of Mayors. In June, he represented North American cities on international panels at the annual CLEAN conference in Aarhus, Denmark. The Bridgeport project is managed by the Ramboll Group, an engineering and design firm in Copenhagen, and several Danish companies have provided support for the project during development.

Ganim actually inherited the thermal loop project from his predecessor in office, Bill Finch, with whom Easton”™s NuPower LLC, a sustainable power developer and investor, first discussed the idea.

Finch “had a very strong interest in green initiatives,” said Daniel Donovan, NuPower co-founder and president. “He immediately saw how this fit in very closely with that. His administration was very supportive, as has been Mayor Ganim”™s.”

Having partnered with Bridgeport on the project three years ago, NuPower had sought state regulators”™ approval to build a fuel cell and sell its energy to United Illuminating, which would help finance the loop. When that effort failed, it joined with city legislators to draft legislation authorizing the thermal loop. While the bill passed in the state House of Representatives, it was vetoed in July by Gov. Dannel Malloy, who said it circumvented proper utility oversight by the Public Utilities Regulatory Authority.

Following the veto, Malloy”™s administration, Ganim and his office, the city of Bridgeport, the Bridgeport legislative delegation, members of the state General Assembly”™s Energy and Technology Committee, the Public Utility Regulatory Agency and the state Department of Energy and Environmental Protection entered into negotiations to strike a compromise. Ultimately the thermal loop was included in the state budget signed into law by Malloy on Oct. 31.

State Rep. Steve Stafstrom, a Democrat representing Bridgeport, said the project not only will reduce the city”™s carbon footprint, but is “expected to bring in about $130 million in privately funded economic development and generate roughly $3 million in property tax revenue to the city on an annual basis.”

Stafstrom said Connecticut should also realize “significant” savings, as the thermal loop will help it cut energy costs at Housatonic Community College, the University of Bridgeport, courthouses and other downtown buildings funded at least in part by the state.

“This is a coup for us,” said state Rep. Joe Gresko, a Stratford Democrat who serves as vice chairman of the legislature”™s environment committee. “Its success is a combination of the willingness of the city of Bridgeport to participate in something like this and the ability of NuPower to stay persistent and make it happen.” Gresko said he hoped to bring the same technology to Stratford.

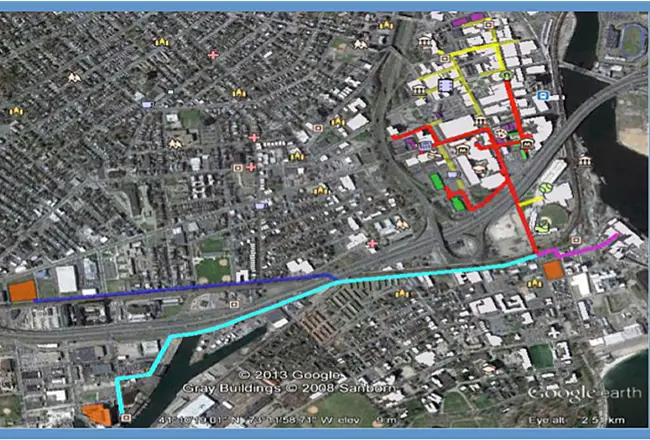

The thermal loop project consists of two phases, the first of which initially involved installing pipeline to supply thermal heat to 2 million square feet of space at a capital cost of about $15 million. NuPower subsequently added 1 million square feet of heating at the campus of the University of Bridgeport at a cost of $5 million, creating a total first-phase piping network of 5.3 miles.

Donovan said the project has a memo of understanding with the University of Bridgeport as a customer and with Wheelabrator Bridgeport as a thermal supplier at its waste-to-energy plant.

The project”™s second phase will add 1.5 miles of piping to heat an additional 3 million square feet of building space at a capital cost of approximately $14 million.

A Danish connection more or less kicked the project off, Donovan said.

NuPower had completed the development of the $250 million, 37.5-megawatt Plainfield Renewable Project in 2013 and at the start of 2014 was looking for other potential opportunities. “We happened to run into a large energy group from Denmark that was visiting Bridgeport,” said Donovan, “and they were saying, ”˜Oh my gosh, this is just like Copenhagen!”™”

Donovan said the Danish contingent was struck by the density of downtown Bridgeport and believed it would be a solid candidate for a thermal loop ”” something that is fairly commonplace in Scandinavia but virtually unknown on this side of the Atlantic.

In September 2015, the Danish government entered into a development agreement with NuPower and Bridgeport, which in turn led to Ganim”™s visit to Denmark this year. Ninety-five percent of Aarhus, Denmark”™s second largest city, uses district thermal heating technology, Ganim said.

Donovan said that, pending final approval from the state Public Utilities Regulatory Authority, he expects construction to begin in the second quarter of 2018.

“It”™ll probably take about nine months to start operations,” he said. “We”™d certainly like to be up and running by the end of next year.”